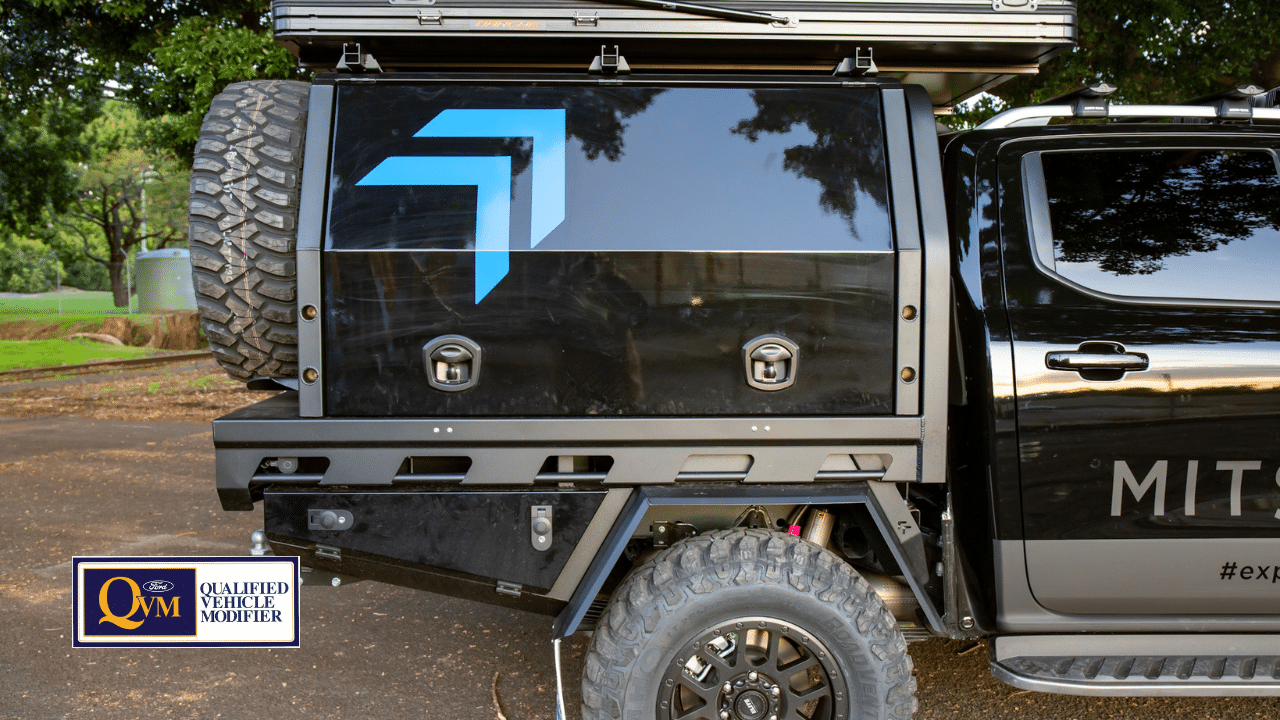

MITS Alloy, Proud Ford QVM Partner

We’re proud to announce MITS Alloy is now officially recognised as a Ford Qualified Vehicle Modifier (QVM) – a major milestone that underscores our commitment to unmatched quality, engineering precision, and customer trust.

Why This Matters for You

When you choose a QVM-Certified MITS Alloy build, you’re choosing:

- Warranty Confidence – Our modifications are Ford-recognised and maintain the base vehicle’s warranty. That means no stress, no voided coverage – just peace of mind.

- Quality Assured – Our design and manufacturing processes meet Ford’s most stringent requirements – including load testing, weight distribution, durability, and safety.

- Ford-Approved Engineering – We work directly with Ford’s Body and Equipment Mounting Manual and CAD data, so your setup integrates seamlessly with your vehicle.

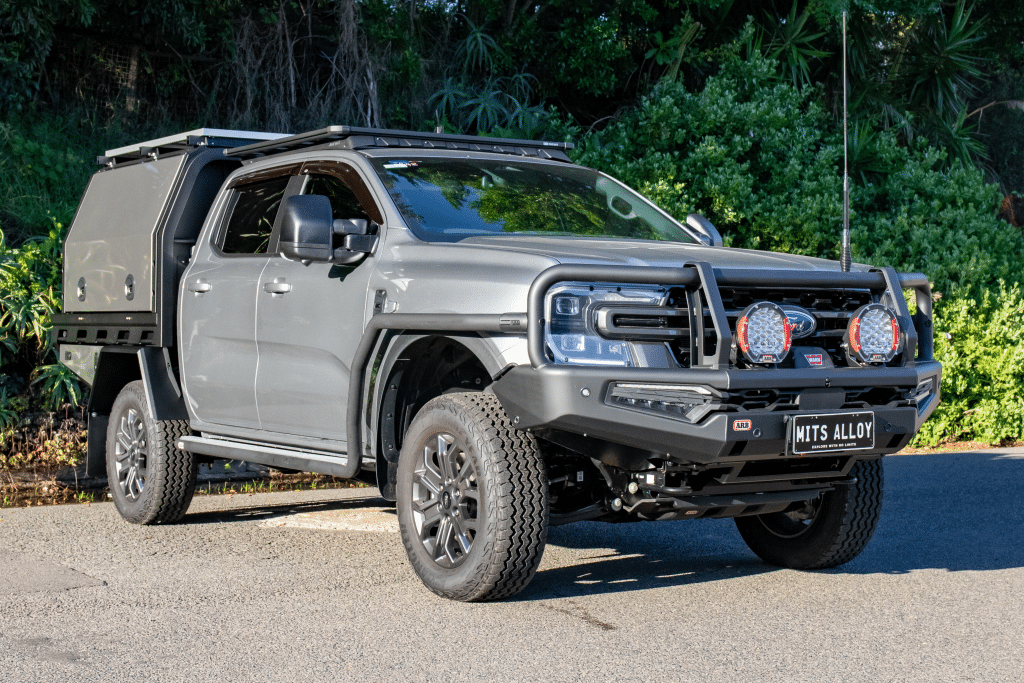

- Fleet-Ready, Adventure-Proven – Our builds are not only tough and practical for work, but adventure-ready for the most demanding off-road journeys.

What is the Ford QVM Program

The Ford QVM program is Ford Australia’s official certification process for vehicle modifiers. It ensures that any aftermarket modifications – think trays, canopies, electrical systems or fit-outs – meet Ford’s rigorous global engineering and quality standards.

Although the QVM program has been running for years in the USA, UK and other global markets, it was only recently introduced to Australia — raising the bar for quality, safety, and consistency in local vehicle modifications.

What Makes a QVM Modifier Different?

To be QVM Certified in Australia, a company must undergo intensive auditing and demonstrate:

- Safe and compliant engineering processes

- Quality manufacturing systems

- Alignment with Ford’s Body and Equipment Mounting Manual (BEMM)

- Proper documentation, testing, and sign-off processes

- Capability to maintain factory warranties on the base vehicle

- It’s not just about quality control; it’s about engineering integration — ensuring the modification doesn’t affect vehicle dynamics, safety, warranty, emissions, or compliance.

The Road to QVM: Why MITS Made the Cut

For us at MITS Alloy, QVM Certification wasn’t just a badge to stick on the website – it was the natural next step in a story that’s always been about pushing boundaries.

We’ve spent years building a reputation for quality in the harshest conditions Australia has to offer. From red dirt mine sites to remote outback tours, our trays and canopies are trusted by those who can’t afford failure.

But we know that real innovation isn’t just about toughness – it’s about trust.

When Ford Australia introduced its globally recognised QVM Program, we saw the opportunity not just to meet expectations, but to set a new standard for what vehicle modifications can be.

It Starts with Self-Assessment

The QVM journey kicked off with a deep internal review. Every weld, every bolt, every process – from design to delivery – had to be measured against Ford’s global standards. We didn’t just check boxes; we pulled apart our own systems to find ways to improve.

We reviewed:

- Engineering processes

- Load testing protocols

- Electrical integration

- Documentation and tracking systems

- Customer support frameworks

- Manufacturing repeatability and consistency

It was a full audit of who we were – and where we wanted to go.

Then Comes Collaboration

From there, we worked closely with the Ford QVM team:

- Entering into confidentiality agreements

- Accessing Ford’s Body and Equipment Mounting Manual

- Integrating Ford’s CAD data into our design processes

This wasn’t just about jumping through hoops. It was about building something smarter. Something safer. Something future-ready.

Once we were confident in our systems, Ford’s engineers visited our facilities in Newcastle to conduct a thorough on-site audit. They looked at:

- Our packages — how we design and finish them

- Our people — from engineering to quality control

- Our process — every step from vehicle arrival to final sign-off

- Our environment — workplace safety, cleanliness, lighting, tooling, compliance

The assessment wasn’t just about the product. It was about our ability to consistently deliver that product, over and over, to the same high standard.

The Outcome

After months of preparation, collaboration and hands-on review, we were awarded Ford QVM Certification.

It was a proud moment – not just for the team in the workshop, but for every customer who has ever trusted us to build something that goes the distance. Because now, it’s not just MITS Alloy saying “you can trust our work” – Ford says it too!

From Factory To Field: Built-In Trust

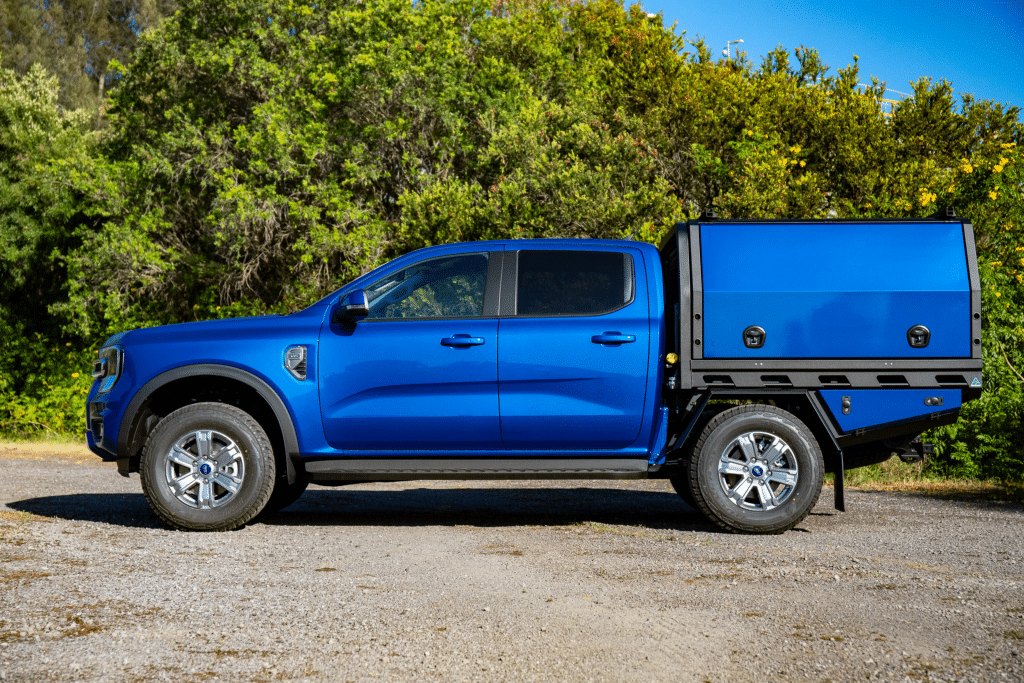

Whether you’re decking out your Ford Ranger for heavy-duty work, building your dream tourer or gearing up to hit the tracks, our QVM Certification means every MITS Alloy component is designed to perform and built to last.

And with Ford’s backing, you get peace of mind that your vehicle’s performance, reliability and warranty are protected.

We’re already putting QVM into action with purpose-built packages across Ford’s Ranger, F150 and F250 range. Speak to our team today to chat through the right tray and canopy setup for your Ford.

Ready To Get Started?

✅ Explore our QVM builds

📞 Speak with a MITS expert today

📍 Find your nearest dealer